Floating Foam Fenders for Sale

10/10/2025Why Can Pneumatic Rubber Fenders Be Used in LPG Operations?

10/14/2025Pneumatic Rubber Fenders Structure

Pneumatic rubber fenders play a vital role in protecting ships and port structures during berthing and towing operations. They absorb impact energy and reduce reaction forces between vessels and docks, ensuring safe and efficient mooring.

For ship owners, port operators, and terminal designers, understanding how these fenders are built is key to proper use, maintenance, and longer service life.

As a leading manufacturer, NANHAI provides high-quality pneumatic rubber fenders engineered for safety, reliability, and performance.

What Are Pneumatic Rubber Fenders

A pneumatic rubber fender is an air-filled, pressure-resistant device used as a buffer between ships or between a ship and a quay.

Compared with solid or foam-filled fenders, pneumatic fenders offer higher energy absorption with lower reaction forces, making them ideal for large vessels, offshore platforms, and ports with variable tide levels.

Main Structure of Pneumatic Rubber Fenders

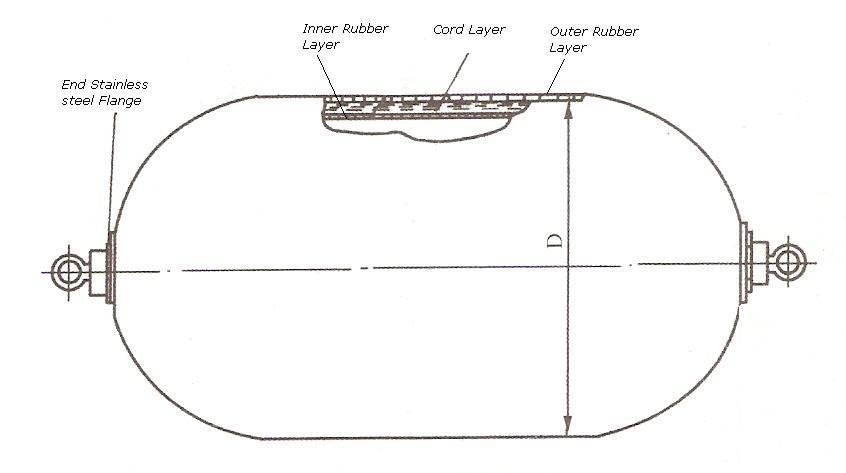

A standard pneumatic fender consists of several layers and components working together to absorb energy and distribute loads safely. Let’s look at its key structural elements from the outside to the inside.

- Outer Rubber Layer (Protective Shell)

The outer rubber layer protects the inner structure from abrasion, seawater, UV rays, and harsh weather. NANHAI uses specially formulated synthetic rubber to ensure flexibility and crack resistance, even under long-term compression. - Reinforced Cord Layers (Tire-Cord Layers)

Beneath the outer shell are multiple layers of synthetic tire cord fabric arranged at precise angles. These layers give the fender high tensile strength and allow it to maintain shape under pressure while evenly distributing stress. - Inner Rubber Layer (Air Tight Lining)

The inner layer seals the air inside the fender. It must be perfectly airtight to prevent leakage and maintain consistent performance. NANHAI’s fenders use a high-quality rubber compound for maximum air retention and elasticity. - End Flanges and Fittings

Each end of the fender is fitted with a metal flange that connects to valves, shackles, or chains. These flanges are made of galvanized or stainless steel to resist corrosion and ensure strong anchoring points for ropes or chains. - Safety Valves and Air Valves

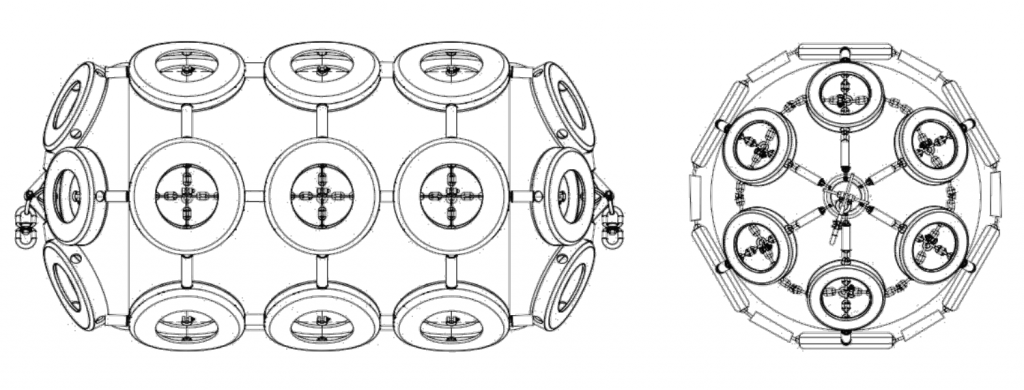

The air valve allows inflation and pressure adjustment, while the safety valve releases excess air if the pressure exceeds the design limit. Proper valve function is essential to maintaining stable fender performance. - Chain or Tyre Net (Optional)

Many fenders are wrapped with a chain or tire net for extra protection against cuts and impact damage. The net helps distribute loads more evenly and prevents the outer rubber from direct contact with the ship’s hull.

Materials and Engineering Focus

Each part of the fender must meet strict material and strength requirements to perform under harsh marine conditions.

- Rubber Compounds: Designed for seawater, UV, and ozone resistance.

- Tire Cord Fabric: Provides structural stability and flexibility.

- Metal Fittings: Hot-dip galvanized or stainless steel to prevent rust.

- Protective Net: Made from heavy-duty chains, tires, or synthetic ropes for added durability.

NANHAI engineers every fender to pass air pressure and strength tests before delivery, ensuring that every product meets ISO17357 or equivalent international standards.

How to Choose the Right Pneumatic Rubber Fender

Choosing the correct fender size and pressure level is essential for safety and cost efficiency.

Here are some main points to consider:

- Vessel Size and Type: Larger ships require higher energy absorption capacity.

- Berthing Energy: The kinetic energy generated when a ship contacts the quay determines the fender size and pressure.

- Installation Method: Floating, suspended, or fixed fenders each require different fittings.

- Environmental Factors: Consider tides, wind, temperature, and wave conditions.

- Standards Compliance: Always choose fenders that meet ISO or equivalent quality standards.

If you’re unsure about the right model, NANHAI provides free technical support and selection guidance for different vessel and port applications.

Installation and Commissioning

Proper installation ensures the fender performs safely and lasts longer.

Follow these steps before and during installation:

- Inspection Before Installation

Check air pressure, valve condition, and surface for damage. - Fixing and Hanging

Use chains, ropes, or brackets according to design requirements. Ensure even load distribution. - Inflation and Adjustment

Inflate to the manufacturer’s recommended pressure and check for leaks. - Safety Check

Verify end fittings, shackles, and hanging points for secure connection before berthing.

Maintenance and Regular Inspection

Routine maintenance is essential to extend the fender’s service life and avoid unexpected failure.

Here’s a simple checklist recommended by NANHAI:

- Before Each Operation

Visually inspect for cuts, cracks, or pressure loss. - Monthly

Check and record air pressure; adjust as needed. - Every Six Months

Inspect valves, chains, and flanges for corrosion. Clean off salt and marine growth. - Annually

Conduct full pressure testing and replace any worn parts such as chains or nets.

Keeping a maintenance record with date, inspector name, pressure readings, and repair notes helps monitor performance and plan replacements in time.

Common Problems and Solutions

Even high-quality pneumatic rubber fenders may face issues during long-term use. Here are some typical problems and quick solutions:

- Air Leakage

Likely caused by valve loosening or surface puncture. Check with soap-water test and repair or replace the valve. - Surface Damage

Caused by contact with sharp objects or rough quay surfaces. Use protective nets and repair minor cuts immediately. - Pressure Drop Over Time

Normal to lose a small amount of air; check monthly and refill to the recommended pressure. - Chain or Shackle Corrosion

Apply anti-corrosion grease and replace parts when thickness loss exceeds 10%.

For serious issues or performance drops, contact NANHAI for professional inspection and repair advice.

How to Extend Fender Service Life

Proper operation habits can significantly increase your fender’s lifespan:

- Maintain correct working pressure (neither overinflated nor underinflated).

- Rotate fenders periodically to prevent uneven wear.

- Clean the surface regularly and avoid prolonged exposure to strong sunlight.

- Store in a cool, dry place when not in use.

- Train your crew to handle and check fenders properly.

With correct use and care, a quality pneumatic rubber fender from NANHAI can serve reliably for many years.

Transportation, Storage, and Disposal

- Transport: Avoid dragging or dropping the fender. Use slings at marked lifting points.

- Storage: Keep in a dry, shaded area, slightly inflated, and away from oil or chemicals.

- Disposal: When the fender is beyond repair, follow local regulations for rubber and metal recycling.

FAQ

Q1: How often should I check the fender pressure?

At least once a month, or before any major berthing operation.

Q2: Can I repair a small crack myself?

Yes, small surface cuts can be repaired using a fender patch kit. For larger damage, contact NANHAI.

Q3: What is the best pressure for operation?

Follow the manufacturer’s specifications; standard working pressures range from 50 to 80 kPa depending on fender size.

Q4: How do I know when to replace my fender?

Replace it if air cannot be retained, rubber becomes brittle, or metal parts show severe corrosion.

Conclusion

Understanding the structure and materials of pneumatic rubber fenders helps ship owners and port operators use and maintain them more effectively.

Each layer and fitting plays a vital role in ensuring energy absorption, safety, and long-term performance.

With proper installation, inspection, and care, your fenders will provide reliable protection for years.

NANHAI is committed to supplying high-quality pneumatic rubber fenders and full technical support — from selection to maintenance — ensuring safe and efficient marine operations.

👉 Contact NANHAI today for expert guidance or a free technical consultation on fender selection and maintenance.