Why Choose Marine Airbags for Marine Cable Laying?

11/05/2025What is the pressure in a pneumatic fender?

11/07/2025Hydro-Pneumatic Submarine Fenders for Sale

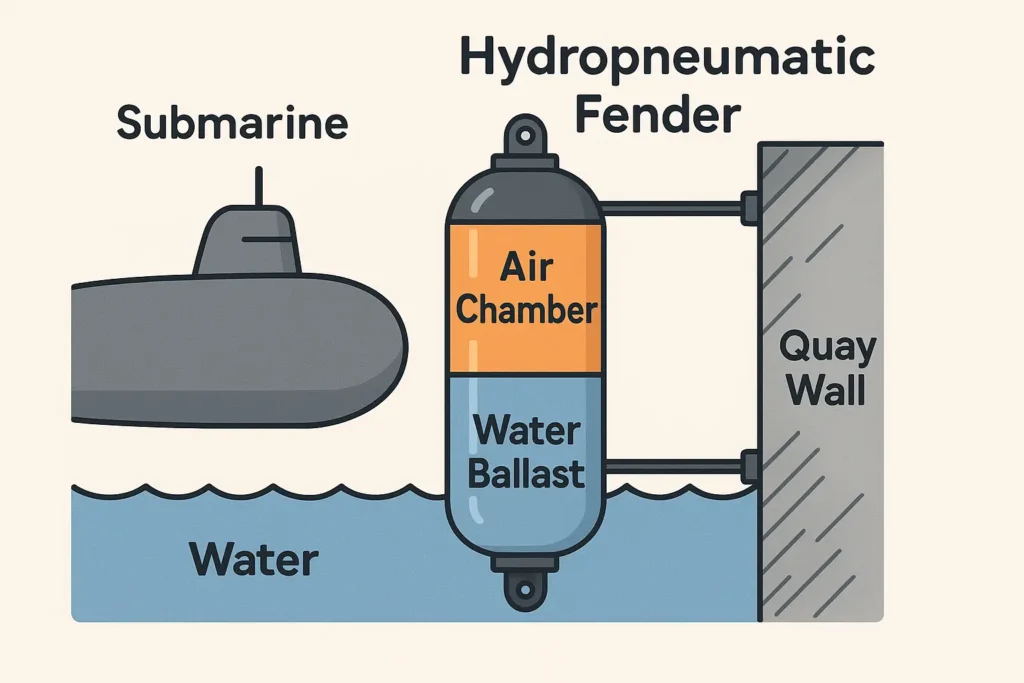

When submarines or semi-submersible vessels dock, they face unique challenges. These ships sit lower in the water, and normal fenders don’t offer enough protection. Hydro-pneumatic submarine fenders solve this issue with a smart mix of air and water. They absorb docking energy smoothly and keep both the vessel and dock safe. Therefore, they are the perfect choice for demanding underwater operations.

What Are Hydro-Pneumatic Fenders?

A hydro-pneumatic fender uses both air and water to spread impact energy evenly. The air adds flexibility, while the water helps control movement. As a result, these fenders protect the hull of submarines and other low-draft vessels from strong impacts.

Moreover, they serve in naval bases, research ports, and offshore terminals, where safety and control during docking are critical.

Main Advantages

- Adjustable Energy Control – You can change the air pressure or water level to fit different docking needs.

- Perfect for Deep or Shallow Drafts – They suit vessels that stay partly or fully underwater.

- Tough and Long-Lasting – Strong rubber and anti-corrosion materials extend their lifespan.

- Quick Installation – Crews can mount or move them easily for different projects.

- Cost Savings – They reduce hull damage, repair costs, and maintenance work.

Overall, hydro-pneumatic fenders combine flexibility, durability, and reliability better than any traditional fender.

How They Work

When a submarine touches the fender, the air and water inside compress. The air cushions the impact, while the water slows the motion. This balance allows smooth energy absorption without sudden shocks.

In addition, operators can adjust the internal pressure through a valve system, which means one fender can serve different vessel types and sizes.

Technical Features

- Energy Absorption: 50–2000 kJ (customized sizes available)

- Pressure Range: 0.5–0.8 MPa

- Working Temperature: -30°C to +70°C

- Material: Reinforced rubber with nylon cord layers

- Outer Cover: Resistant to seawater, oil, and UV rays

- Mounting Options: Chains, support frames, or floating systems

These features ensure reliable performance even in harsh marine environments.

Where They Are Used

You can find hydro-pneumatic fenders in many demanding applications:

- Submarine Bases – For safe berthing, repair, and loading.

- Semi-Submersible Platforms – For docking and transfer operations.

- Shipyards and Research Ports – For testing and maintaining underwater vehicles.

- Offshore Projects – For temporary or mobile berthing systems.

For example, one naval port switched from fixed fenders to hydro-pneumatic ones. As a result, docking time dropped by 25%, and maintenance costs fell because the hull stayed undamaged.

Installation and Maintenance

Installing hydro-pneumatic fenders is simple. Crews can secure them with chains or frames along the quay or floating dock.

To keep them in top shape, teams should:

- Check air and water pressure regularly.

- Inspect valves and hoses.

- Clean the outer rubber surface.

- Replace worn seals on time.

In most cases, these checks happen once or twice per year. This simple maintenance routine ensures steady performance and safety.

Safety and Quality

Each fender goes through strict testing before delivery. The process includes:

- Pressure and leakage tests

- Energy absorption performance tests

- Material quality checks

Thanks to these steps, every product meets high marine standards. Moreover, clients receive full reports to confirm the test results.

Comparison with Other Fender Types

| Fender Type | Energy Control | Maintenance | Best For |

|---|---|---|---|

| Hydro-Pneumatic Fender | Adjustable (air + water) | Low | Submarines, semi-subs |

| Pneumatic Rubber Fender | Air only | Medium | Cargo ships |

| Fixed Rubber Fender | None | Low | Simple docks |

As the table shows, hydro-pneumatic fenders provide greater control and flexibility. On the other hand, traditional fenders work best for simple, above-water vessels.

Economic Benefits

Hydro-pneumatic fenders do more than just protect vessels. They also bring long-term savings:

- Reduce repair and maintenance costs

- Extend dock and vessel lifespan

- Cut downtime between operations

- Work across different locations and vessel types

Therefore, they are one of the most cost-effective docking protection systems in the marine industry today.

Frequently Asked Questions (FAQ)

Q1: What makes hydro-pneumatic fenders different from normal pneumatic ones?

A: Hydro-pneumatic fenders use both air and water, offering better stability for submarines and semi-subs.

Q2: Can they handle extreme temperatures?

A: Yes. They work smoothly from -30°C to +70°C.

Q3: How long can they last?

A: With regular care, they can perform well for more than 10 years.

Q4: Are they easy to install?

A: Yes. Crews only need standard marine tools and mounting chains.

Conclusion

Hydro-pneumatic submarine fenders deliver safe, flexible, and reliable protection for submarines and semi-submersible vessels. They make docking smoother, cut maintenance costs, and extend vessel life.

If you are planning a new docking project or upgrading an existing one, contact us today for a custom hydro-pneumatic fender solution designed to fit your exact needs.