Advantages of ribbed pneumatic fenders

07/24/2025Why ship to ship transfer?

07/25/2025Application areas of roller fenders

1. Introduction-roller fenders

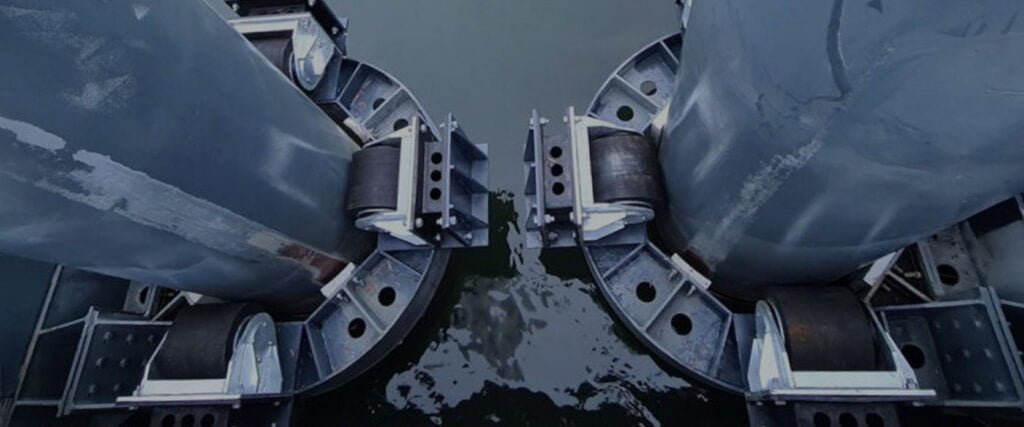

Roller fenders guide ships safely when they dock. It rolls as the vessel touches it, reducing friction, absorbing impact, and protecting both the ship hull and the dock edges.

2. How Roller Fenders Work — and What Makes Them Valuable

Roller fenders use a rubber or elastomer wheel mounted on a steel shaft within a strong metal frame. They spin on stainless-steel or composite bearings for smooth movement.

When a boat touches the fender, the wheel rotates. This rotation reduces friction and keeps the vessel moving gently. The fender also compresses to absorb energy—often up to 40% deformation—for effective shock protection.

Benefits in a look:

- Smooth vessel guidance

- Low reaction force and high energy absorption

- Very low friction and minimal maintenance

3. Applications & Real‑World Examples

Marine engineers typically install roller fenders in key areas:

- Dry dock entrances and dock walls to direct ship entry and prevent hull contact

- Lock approaches and narrow channels, where precise alignment matters with limited maneuver space

- Exposed berth corners, where collisions risk high local damage, and fenders help protect edges

Companies often stack fenders in single, double, or triple rows. Designers angle them or space them side-by-side to match the vessel hull profile exactly.

4. Design Options & Installation Tips

Roller fenders come in standard models but almost always need custom sizing:

- Stacked configurations handle tidal variations or height differences, e.g., single up to triple stacks

- Angled placement aligns with the flare of the vessel hull

- Side-by-side alignment steers vessels through narrow approaches

Ask a designer to review your site plans, vessel size, tidal range, and intended berthing orientation. That ensures you choose the right spacing, tilt, and row configuration for safe docking.

5. Maintenance & Service Life

Roller fenders require low upkeep—thanks to sealed bearings and sturdy frames. Yet, a regular care routine can extend their life:

- Inspect visually every month. Look for signs of rust, wear, or wheel issues.

- Perform detailed checks yearly or semi-annually, including internal bearings and frame bolts. Keep maintenance logs for trends and planning.

- Clean regularly: remove salt, marine growth, and dirt with mild detergent or low-pressure wash, then dry completely. Apply protective coatings where recommended.

- Monitor for cracks or abrasion and repair small damage early. Replace components if wear exceeds safe limits.

With proper care, roller fenders typically last 5 to 10 years, and sometimes much longer in mild conditions.

6. Emerging Trends & Future Outlook

We see more innovation in marine safety gear:

- Smart sensors and IoT monitoring, embedded to track wheel wear and alert operators when maintenance is due

- Advanced composite and corrosion-resistant materials that resist UV, saltwater, and abrasion longer

- Modular, adjustable roller units, allowing reconfiguration when docks or vessel types change

- Project-specific turnkey solutions, integrating design, delivery, installation, and ongoing support from brands like Trelleborg and Shibata

7. Summary

Roller fenders offer a smart mix of guidance and energy absorption. They reduce friction, cushion dockings, and require little maintenance. You’ll find them in dry docks, lock entrances, berth corners, and narrow channels.

With simple but regular checks and cleaning, they can give many years of reliable service. For optimal results, talk to a marine fender specialist to design the right layout for your dock and vessel types.