Why Cruise Terminals Prefer Foam Filled Fenders?

07/10/2025Independent components affecting pneumatic rubber fenders

07/11/2025Tugboat Fenders for Heavy-Duty Marine Operations

Why This Issue Is Necessary & Urgent

In today’s fast-paced marine industry, overworked tugboats face non-stop pressure—both literally and figuratively. Every time a tug pushes a massive container ship or navigates a crowded harbor, the risk of hull damage, structural impact, or costly repairs is real. Just last spring, a routine docking went wrong when a worn-out fender failed mid-operation, delaying schedules and racking up extra costs. Investing in heavy-duty tugboat fenders isn’t an option; it’s a survival strategy.

What Makes Tugboat Fenders Essential in Marine Operations?

Tugboat fenders are the frontline defense during high-stakes maneuvers. Crafted from ultra-durable rubber or composite materials, they absorb shock, reduce hull pressure, and withstand abrasion and UV exposure. Whether guiding super‑tankers or icebreakers, quality fenders keep operations smooth and vessels safe.

Why NANHAI Marine Fenders Stand Out

As a worldwide leader in marine fenders and ship fenders, NANHAI brings nearly 20 years of R&D excellence.

- Superior materials: from SBR and neoprene to specialty rubbers like EPDM and chlorosulfonated polyethylene.

- Broad-certified quality: ISO 9001, PIANC-compliant, tested by BV, CCS, LR, TUV, and more.

- Smart design: options like M‑type and W‑type for varied dock ergonomics, plus cylindrical and keyhole styles.

- Low maintenance: engineered for easy installation, minimal upkeep, and long service life.

Top Tugboat Fender Types You Need to Know

Tug Cylindrical Fenders: Widely used for bow/stern protection; noted for their simplicity and durability.

W‑Type Fenders: Slim design for better contouring—economical yet efficient.

M‑Type Fenders: Broad contact surface ideal for pushing larger vessels, distributing load more evenly.

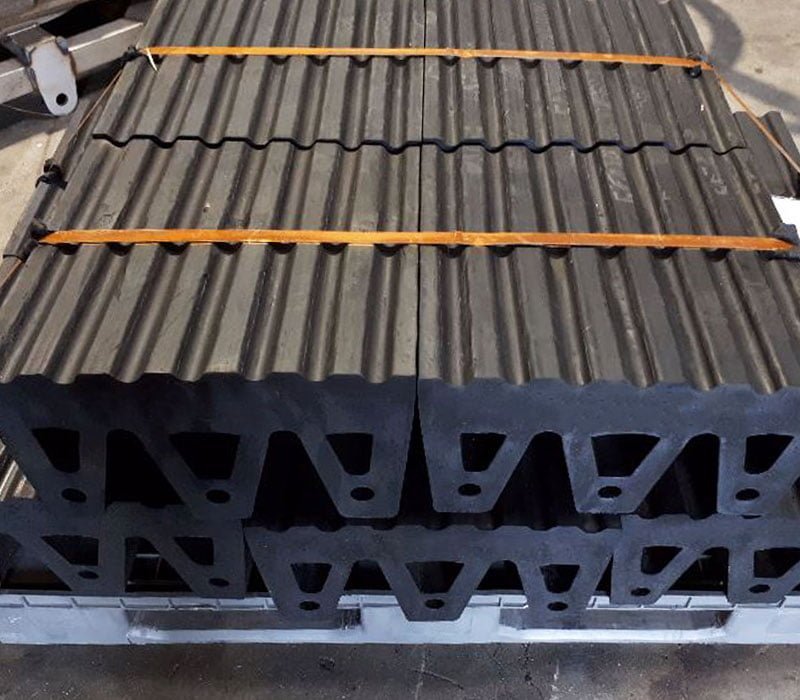

Block Fender: Block Fenders have a traditional ‘keyhole’ profile, which is strong and ideal for heavy-duty applications. There is a choice of grooved or flat face fenders depending on the required friction levels.

How to Choose the Right Fender for Your Tug

- Evaluate Impact Energy: Use PIANC formulas—berthing energy depends on mass × velocity².

- Select Proper Shape: Cylindrical for general use, W or M for precision pushing, pneumatic for soft-contact needs.

- Material Consideration: Choose rubbers robust against UV, salt, abrasion, and chemical exposure—NANHAI provides options like EPDM, neoprene, and Haipalong.

- Certifications Matter: Ensure ISO 17357 for pneumatic fenders, ISO 9001 for quality, PIANC compliance, and third-party testing.

- Installation & Maintenance: Look for bolt-in fenders, modular systems, and easy-replacement designs to reduce downtime.

FAQ

What are marine fenders?

Marine or ship fenders are buffer devices used in ship-to-dock and ship-to-ship operations, designed to absorb kinetic impact while minimizing reaction forces.

How do pneumatic (Yokohama) fenders differ from solid rubber ones?

Pneumatic fenders use compressed air to absorb impact gently and self-adjust on water—they’re ideal for liquid cargo vessels; solid rubber fenders offer higher energy absorption but a more rigid response.

Which tugboat fender type is best for pushing barges?

M‑type fenders provide larger contact surfaces and better load distribution, making them ideal for pushing heavy barges and ships.

How to calculate the right fender size?

Use berthing-energy formulas from PIANC guidelines, factoring in vessel displacement, speed, hull geometry, docking structure, and tidal range.

Optimizing your tugboat fleet with NANHAI marine fenders means peace of mind, fewer repairs, and safer, smoother heavy-duty operations. Interested in a free assessment or quote? Reach out today—your next docking operation deserves elite protection.