Can tug boats handle rough seas?

12/05/2025How Is Oil Transferred at Sea?

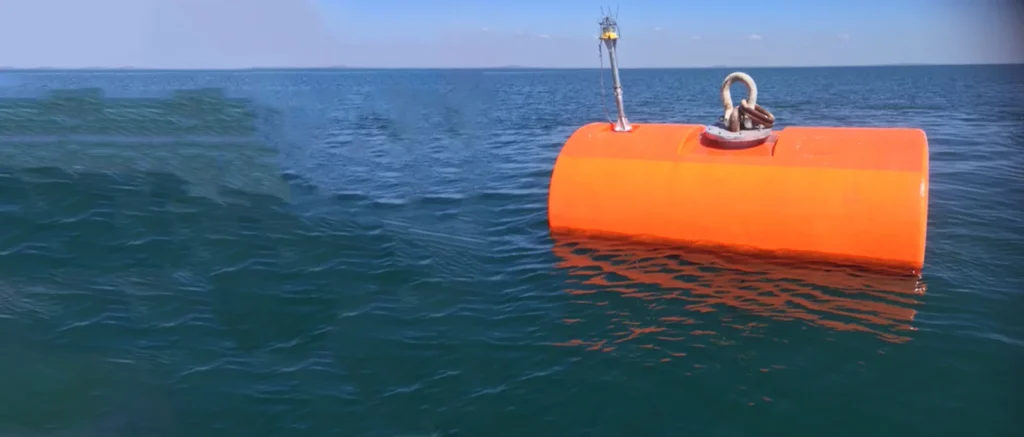

12/11/2025What Is a Barrel Mooring Buoy?

A barrel mooring buoy is a barrel-shaped floating device that gives boats and floating equipment a safe point to tie to. It keeps the mooring connection above the water, so operators can secure their vessels easily. Because the design is simple and dependable, many harbors, aquaculture sites, and offshore projects rely on this type of buoy every day.

How a Barrel Mooring Buoy Works and Its Main Features

A barrel mooring buoy acts as the visible part of a mooring system. It connects to a chain or rope below the water, and that line links to a seabed anchor. When a boat ties to the buoy, the anchor system holds the load while the buoy keeps the connection accessible.

The barrel shape creates strong buoyancy and excellent stability, even when waves increase. Most buoys use steel, plastic, or polyethylene because these materials resist corrosion and impacts. In addition, bright colors and reflective bands help operators find the buoy quickly during the day or at night. These practical features make the buoy easy to handle and reliable in long-term marine use.

Common Applications

Barrel mooring buoys appear in many marine environments. They serve different purposes, and several industries depend on them daily. For example:

- Small boats, fishing vessels, and personal watercraft use them as simple mooring points

- Ports and marinas set them as temporary or overflow mooring positions

- Offshore projects use them to position floating equipment

- Aquaculture farms rely on them to keep cages, nets, or workboats in place

Advantages and Maintenance of Barrel Mooring Buoys

Barrel mooring buoys offer several important benefits. First, they cost less than building fixed mooring structures. Moreover, operators can install them quickly and use them in shallow or deep water. The design also delivers high buoyancy and strong impact resistance, so the buoy performs well in changing marine conditions.

Regular maintenance keeps the buoy safe. Operators should inspect the mooring chain, shackles, and connection points for wear. In addition, removing marine growth improves performance. Steel buoys need surface coating checks, while polyethylene models require inspections for cracks or UV damage. With proper care, the buoy stays reliable for many years.

How to Choose the Right Barrel Mooring Buoy

Choosing the right buoy depends on several factors. You should evaluate the required buoyancy, the type of material, and the water depth. Moreover, the expected load and sea conditions also guide the selection. When these elements match the environment, the buoy can handle the intended mooring forces safely.

Conclusion

A barrel mooring buoy offers a simple, reliable, and cost-effective way to secure vessels and floating equipment. Its strong buoyancy, durable materials, and easy installation make it a popular choice in harbors, aquaculture sites, and offshore operations. With proper selection and routine maintenance, it provides long-lasting performance.

FAQ

1. What is a barrel mooring buoy used for?

It serves as a mooring point for small boats, floating equipment, and offshore structures.

2. What materials are commonly used to make barrel mooring buoys?

Manufacturers often use polyethylene, plastic, or steel.

3. Do barrel mooring buoys require maintenance?

Yes. Operators should inspect the chain, connectors, buoyancy, and surface condition regularly.

4. Are barrel mooring buoys suitable for deep water?

Yes, as long as the mooring system and anchor match the site conditions.