Floating Pneumatic Rubber Fenders Factory — NANHAI Direct Supply

10/07/2025Floating Foam Fenders for Sale

10/10/2025What Is the Air Bag Launching of Ships (Ship Launching Airbags)?

Ship launching airbags are an efficient, safe, and flexible way to launch or move ships.

Instead of using traditional slipways or dry docks, this method places several high-strength rubber airbags under the hull. By inflating them, the airbags create buoyancy and rolling power, allowing the vessel to slide into the water smoothly.

Because it doesn’t require fixed facilities or heavy cranes, this method saves money, shortens construction time, and works in many different locations. Today, ship launching airbags are widely used by shipyards, ship owners, and marine engineering companies around the world. Even large civil projects, such as caisson sinking, use this technology.

NANHAI, one of the world’s leading manufacturers of ship launching airbags, has been focusing on this field for many years. We provide complete design and launch solutions. All NANHAI products have passed EU Deforestation Regulation (EUDR) certification, so shipyards in the EU can purchase with full confidence.

1. How Ship Launching Airbags Work

The ship launching process includes four main stages:

- Placement – Several airbags are evenly positioned under the ship’s keel.

- Inflation – Air is pumped into the airbags to lift the ship off its supports.

- Rolling – By adjusting air pressure and release order, the ship rolls forward toward the water.

- Release – When part of the ship enters the water, the airbags are deflated and recovered.

Throughout the process, ship launching airbags play three roles — supporting, cushioning, and rolling.

Their multilayer reinforced rubber structure can handle high pressure, resist twisting, and roll smoothly even on uneven ground.

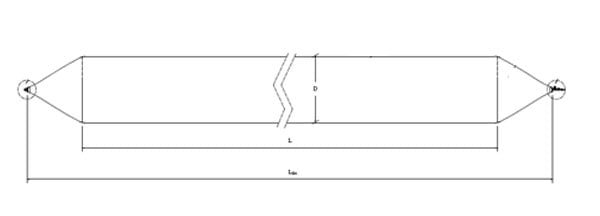

2. Structure and Features of Ship Launching Airbags

- Main Material: Multi-layer high-strength synthetic rubber and cord layers (usually double-strand). NANHAI uses three-strand tire cords, providing up to 4.5× higher safety factor.

- End Design: Cone-shaped or flat-end designs for easy inflation and deflation. NANHAI has also developed double-end inflatable and liftable ship launching airbags for greater flexibility.

- Sizes: Common diameters range from 0.8 m to 4 m, with lengths up to 33 m. Custom sizes are available for different vessel types and launch angles.

- Reusable: High-quality marine airbags can be reused 80–100 times or more.

3. Comparison with Traditional Launching Methods

| Comparison | Slipway Launch | Dry Dock | Airbag Launch |

|---|---|---|---|

| Infrastructure Cost | High | Very High | Low |

| Site Requirement | Fixed | Fixed | Flexible |

| Construction Time | Long | Long | Short |

| Safety | Medium | Moderate | Highly Controlled |

| Suitable Vessel Size | Medium–Large | Large | Small to Large |

| ROI Speed | Slow | Slow | Fast |

For most shipyards, using ship launching airbags means lower investment, shorter project cycles, and higher efficiency.

4. Value for Different Users

1️⃣ For Ship Owners

Pain Points:

- Renting a dry dock or slipway is expensive.

- Waiting time is long and location options are limited.

Benefits:

- Launch or move ships quickly, saving time and rental costs.

- Ideal for temporary jobs, emergency repairs, or coastal operations.

- Requires almost no upfront investment if using rental or service models.

Summary:

Flexible, low-cost, and mobile — the perfect choice for independent ship owners.

2️⃣ For Small & Medium Shipyards

Pain Points:

- Can’t afford expensive slipways or docks.

- Small batch orders and short delivery times.

Benefits:

- No need for fixed infrastructure — launch ships directly with airbags.

- Quick payback period; one airbag set can serve multiple projects.

- Easy to move, deploy, and share between projects.

Summary:

Helps smaller shipyards expand capacity and take on more contracts while reducing capital costs.

3️⃣ For Large Shipyards

Pain Points:

- Existing slipways are often busy or under maintenance.

- Special ship types need flexible launching methods.

Benefits:

- Works as a backup or supplement to slipway systems.

- Ideal for emergency, modular, or offshore projects.

- Can be customized for heavy loads and synchronized control systems.

Summary:

Improves flexibility and production efficiency, offering backup support for special tasks.

5. Cost and Economic Benefits

The total cost of using ship launching airbags includes the airbags themselves, an air compressor, towing equipment, and labor.

Compared with building a slipway or renting a dry dock, total expenses can be reduced by 50–80%.

Since ship launching airbags are reusable, their cost per use drops sharply over time — a true one-time investment, long-term return solution.

6. Safety and Operation

- Operation: Keep pressure balanced and avoid uneven loads during rolling.

- Risk Control: Add spare airbags and use pressure monitoring systems.

- Maintenance: Clean, dry, and store in a cool, shaded place after use.

With proper training and setup, the entire process is safe, stable, and fully controllable.

7. Typical Case Studies

- Case 1 – Fishing Vessel Owner:

Used 8 airbags to launch a 300-ton vessel in only four hours — no slipway needed. - Case 2 – Medium Shipyard:

Replaced a traditional slipway system and saved about 60% in annual maintenance costs. - Case 3 – Large State-Owned Shipyard:

Used airbags at a remote site to transport ship modules for an emergency project.

8. FAQ

Q1: How much weight can airbags handle?

Up to thousands of tons, depending on the number and layout of airbags.

Q2: How long do airbags last?

Typically 80–100 uses or more with proper care.

Q3: Is it safe?

Yes. Professionally designed and properly placed airbags are very safe, with pressure control and backup plans.

Q4: Can they handle large vessels?

Yes. Multiple airbags can work together for synchronized launching.

9. Choosing a Reliable Supplier

When buying or renting ship launching airbags, choose a manufacturer that:

- Has real project experience and engineering know-how;

- Provides design calculations and on-site guidance;

- Holds ISO 14409 certification and third-party test reports;

- Offers after-sales training and maintenance support.

10. Conclusion and Next Steps

Ship launching airbags have become an essential part of modern shipbuilding.

They combine low cost, high safety, and strong flexibility — helping companies of all sizes work faster and smarter.

✅ For Ship Owners: Save time and cost.

✅ For Small Shipyards: Cut investment and grow capacity.

✅ For Large Shipyards: Add flexibility and boost productivity.

If you want to learn more about airbag models, design calculations, or see real project videos, contact a professional manufacturer NANHAI for ship launching airbags technical support and quotation.