High-Performance Pneumatic Fenders for Ship and Port Protection

05/19/2025How to Choose the Right Ship Fenders?

05/21/2025What is the construction of pneumatic fenders?

Pneumatic fenders, also known as pneumatic rubber fenders or floating fenders, play a critical role in ship-to-ship and ship-to-dock operations. These large, air-filled devices absorb kinetic energy during berthing, protecting both vessels and port infrastructure.

Why Is This Important Now?

In today’s busy ports, the risk of collisions and docking accidents increases as global shipping volumes rise. For example, imagine a tanker arriving at port during rough tides. Without a high-quality pneumatic fender in place, the ship could strike the dock, causing severe structural damage.

Choosing the right fender and understanding its construction helps maritime professionals prevent costly downtime and ensure safety. Let’s explore how pneumatic fenders are built—and why each layer matters.

How Are Pneumatic Fenders Constructed?

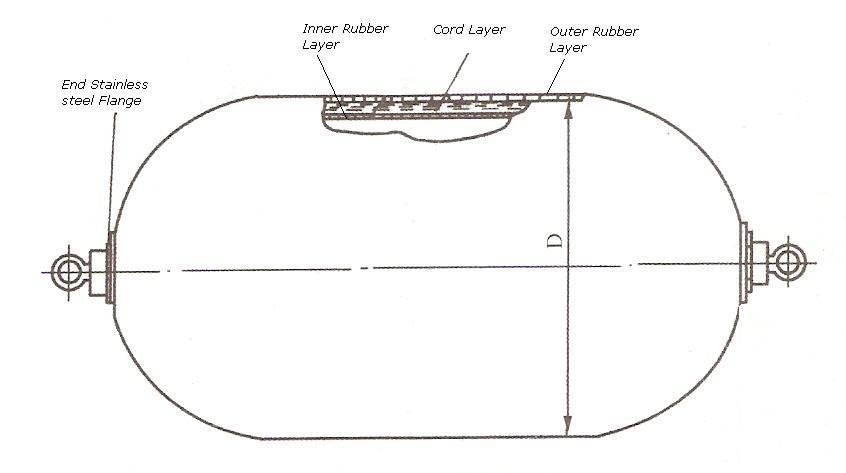

Pneumatic fenders consist of several durable layers that work together to absorb impact and resist external forces.

1. Outer Rubber Layer

The tough outer shell resists wear and environmental damage. Manufacturers typically use rubber compounds that withstand saltwater, UV rays, and extreme temperatures. This protective layer extends the fender’s lifespan, especially in harsh marine environments.

2. Reinforcement cord Layer

Underneath the outer layer lies a mesh of synthetic tire-cord fabric. This material reinforces the fender’s structure and distributes internal stress. As a result, the fender maintains its shape and pressure even during heavy compression.

3. Inner Rubber Layer

This internal liner holds the compressed air inside the fender. It acts like a balloon, retaining the fender’s shape and allowing it to absorb impact without deflating.

4. End Flanges and Safety Valves

At both ends of the fender, steel flanges allow secure connection of air valves. Larger fenders (typically over 2500 mm in diameter) often include a safety valve. This valve releases excess pressure to avoid damage during over-compression.

5. Chain and Tyre Net (Optional)

Many fenders include a chain-and-tyre net for extra protection. The net shields the rubber body from sharp or abrasive surfaces during frequent contact with vessels or docks.

Types of Pneumatic Fenders

You can choose from several types, depending on your vessel or dock environment:

Chain & Tyre Net Type: Most common; great for oil terminals and large vessels.

Sling Type: No external net; lighter and easier to install for smaller ships.

Ribbed Type: Uses raised rubber ribs instead of a net; provides solid protection while saving weight.

Hydro-Pneumatic Type: Designed for submarines, it remains vertical in water to protect underwater hulls.

Why Use Pneumatic Fender for Ships?

Compared to other types of marine fenders, pneumatic ones offer several benefits:

- They absorb more energy with less reaction force, reducing the risk of hull damage.

- They adapt to tidal changes, unlike fixed fenders that may sit too high or too low.

- They install quickly, thanks to their relatively lightweight structure.

- They last for years with minimal maintenance.

Consequently, many ports around the world rely on pneumatic fenders to protect ships of all sizes—from container vessels to LNG carriers.

People Also Ask

What materials do manufacturers use in pneumatic rubber fenders?

They use a combination of rubber (for flexibility and weather resistance) and synthetic tire-cord fabric (for strength and pressure retention).

How do pneumatic fender work?

They absorb kinetic energy using internal air pressure. As ships press against them, the fender compresses and cushions the impact.

Why are pneumatic fenders better than foam fenders?

Pneumatic fenders handle greater impact forces and react more gently to the ship’s hull. They also handle tidal variations better than foam fenders.

Can I use pneumatic fenders for all vessel types?

Yes. Different fender types support tankers, cargo ships, submarines, and even cruise liners. The key is selecting the right size and structure for your application.

Final Thoughts

If you work in maritime logistics or ship operations, you shouldn’t overlook the construction of pneumatic fenders. Their layered design and high energy-absorbing capacity can protect your investment, reduce downtime, and keep your crew and infrastructure safe.

Need help choosing the right pneumatic fender for your ship? Contact us today and speak with our marine protection specialists.