Hydro-Pneumatic Submarine Fenders for Sale

11/06/2025What Are the Airbags Used for Ship Launching?

11/10/2025What is the pressure in a pneumatic fender?

1. Why Fender Pressure Matters

When a ship comes alongside a dock, a lot of force is involved. The pressure inside a pneumatic fender is what controls how much energy it can absorb and how safely it can protect both the ship and the quay wall.

If the pressure is too low, the fender won’t perform well. Too high, and it may shorten the fender’s lifespan. So, understanding the right pneumatic fender pressure is key for every port engineer and ship operator.

2. How Pneumatic Fenders Work

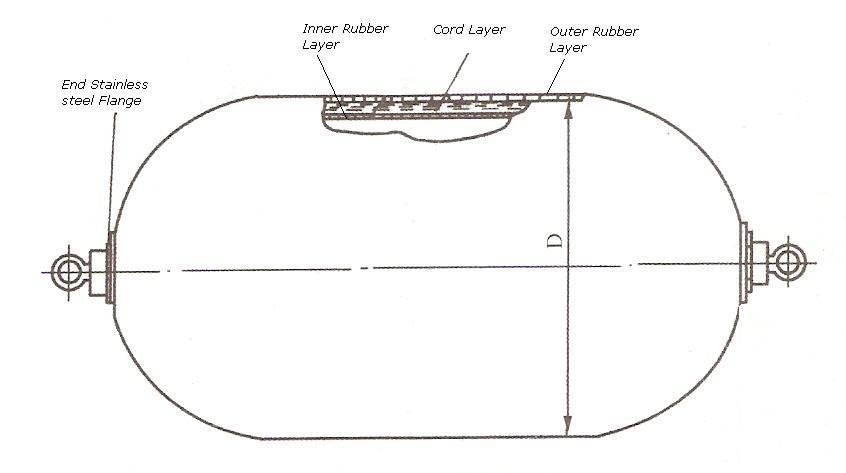

A pneumatic rubber fender is basically an air-filled, floating cushion between the ship and the dock.

When the ship presses against it, the air inside compresses and absorbs the impact. Because air is flexible, floating pneumatic fenders can handle different vessel sizes and berthing angles — that’s why they’re widely used at ports, offshore platforms, and STS (ship-to-ship) operations.

3. The Role of Pressure in Fender Performance

The internal air pressure defines the fender’s reaction force and energy absorption capacity.

- Higher pressure = stronger reaction and faster rebound.

- Lower pressure = softer contact and more cushioning effect.

For large fenders (diameter 2.5m or above), safety becomes even more critical.

That’s why NANHAI pneumatic marine fenders are all equipped with built-in pressure relief valves, which prevent overpressure during extreme compression or temperature changes.

4. Common Pressure Standards: 50 kPa vs 80 kPa

In most projects, pneumatic fenders are made to two main pressure levels — 50 kPa and 80 kPa.

Both meet ISO 17357 standards, but each has its advantages:

- 50 kPa (low pressure ISO 17357-2:2014): Ideal for normal harbor operations, longer lifespan, less maintenance.

- 80 kPa (high pressure ISO 17357-1:2014): Provides higher reaction force and faster recovery, suitable for heavy-duty berthing and offshore use.

However, higher pressure isn’t always better. For many ports, 50 kPa fenders perform more efficiently, balancing safety, cost, and durability.

5. How to Maintain the Right Fender Pressure

Checking air pressure regularly is simple but vital.

- Use a calibrated air gauge every few months.

- Keep the pressure within ±5% of the rated value.

- Avoid sudden deflation or exposure to high heat sources.

Well-maintained pneumatic marine fenders can last more than 10 years even under frequent berthing conditions.

6. Extreme Climate Reliability

At NANHAI, we’ve upgraded our rubber compound formula.

Our latest pneumatic fenders maintain stable elasticity and pressure even at –50°C, ensuring dependable performance in Arctic and cold-weather ports.

This makes them ideal for oil & gas terminals, polar research vessels, and offshore installations.

7. Real-World Safety Impact

According to port operation reports, terminals that adopted pneumatic fenders showed a 40% reduction in berthing damage incidents compared to those using traditional solid fenders.

The ability to adjust internal air pressure for different ship types dramatically improves safety and reduces repair costs.

8. Why Choose NANHAI Pneumatic Fenders

As a professional manufacturer, NANHAI offers a full range of pneumatic rubber fenders built to ISO 17357 standards.

We design, test, and certify every fender to deliver the best balance of safety, energy absorption, and long-term reliability — from small coastal ports to large offshore projects.

Contact the NANHAI team today to get expert advice and the most competitive quote for your port or ship-to-ship operations.

9. FAQ

Q1: What is the normal pressure for a pneumatic fender?

Most fenders use 50 kPa or 80 kPa internal pressure depending on the size and usage environment.

Q2: How often should I check the fender pressure?

We recommend checking every 3 to 6 months and adjusting if pressure drops more than 5%.

Q3: Can pneumatic fenders work in cold weather?

Yes. NANHAI pneumatic fenders keep full performance even at –50°C, thanks to upgraded rubber materials.

Q4: What happens if pressure is too high?

If pressure exceeds the design value, large fenders (≥2.5m) will automatically release excess air through pressure relief valves for safety.