Types of ports and what marine fenders are suitable for them

07/31/2025What are composite fenders?

07/31/2025How submarines dock?

1. Introduction

Submarine docking means guiding a submarine into a safe mooring spot. Docking may take place on the surface or in a dry dock for maintenance. Docking helps with crew change, refueling, repairs, and loading or unloading supplies.

2. Key Equipment for Submarine Docking

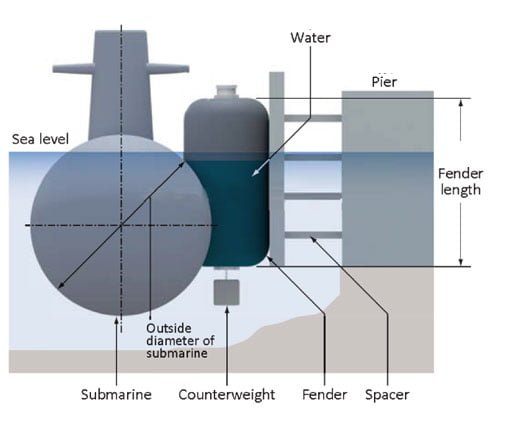

- Hydro‑pneumatic fenders

These fenders are special for submarines. They hold a mix of water and air, and have counterweights that keep them upright. This makes sure the fender touches the submarine hull softly and stays vertical underwater. These fenders absorb energy well and put very low pressure on the hull, which helps avoid damage to delicate coating or tiles on the submarine. You can fine-tune them by changing the air‑to‑water ratio and pressure to fit the hull shape and water depth. - Submarine foam fenders

These are solid, cannot leak, and resist tough conditions like ice or extreme cold. They protect the hull even when pierced or damaged. - Camels (buffer systems)

Camels are floating blocks or tubes placed between submarine and pier. They keep the submarine at a safe gap and protect both sides. - Tugs, bow thrusters, and dynamic positioning

Tugboats and onboard thrusters help align the submarine and move it gently into position against the pier. - Keel blocks and docking cradles

In a dry dock, these support the submarine’s weight. The docking cradle and blocks hold the hull firmly off the ground. - Mooring lines and hardware

Crews use lines like breast lines, spring lines, and bollards to secure the submarine once it’s in place.

3. Surface Berthing (Docking at Sea Level)

- The crew ties up hydro‑pneumatic fenders to the pier at the correct depth and spacing.

- They set camels between the pier and the hull to keep a safe distance.

- Tugboats or onboard thrusters move the submarine slowly toward the pier.

- As the submarine touches the fenders, these absorb the impact. They compress gently and cushion the hull. The low pressure prevents damage to the submarine’s sensitive coatings.

- Crews fasten mooring lines carefully, and they watch for line snap‑back zones or shifting gear. They stay alert to avoid sudden cable snap dangers.

4. Dry Docking (Full Cycle Docking)

Dry docking takes submarines out of the water for in-depth repairs or upgrades:

- Engineers schedule full-cycle docking to inspect hull, renew systems, paint, and upgrade electronics.

- The submarine enters the dry dock while one end stays afloat.

- Workers place keel blocks under the hull in precise spots.

- They close the dock gate and pump out water until the hull rests on blocks.

- Then, teams work on cleaning, inspection, repairs, and system upgrades.

- After work finishes, they flood the dock, unlock the submarine, and refloat it gently.

5. Safety and Technical Details

- Hydro‑pneumatic fenders deliver low reaction forces. They reduce the risk of damage to acoustic tiles or hull coatings. The initial pressure and buoyancy level must fit the hull profile and water depth.

- Crews tune the air‑to‑water mix and pressure carefully to adjust draft and cushioning behaviour.

- Teams prepare emergency plans for line breakage or fender shifts during mooring.

- They always consider wind, current, tidal changes, and pier layout when docking.

6. Real‑World Use and Cases

Organizations like Trelleborg, NANHAI, and others build hydro‑pneumatic fenders that meet ISO standards. These fenders serve submarines at naval bases and oil rig jetties. They offer flexible designs, easy installation, low-cost upkeep, and high durability in harsh climates.

Hydro‑pneumatic fender systems let navies dock subs safely and efficiently—even at deeper berths where traditional fenders won’t reach.

7. Conclusion

Submarine docking needs the right gear and careful steps. Hydro‑pneumatic fenders protect the hull underwater and absorb impact softly. Foam‑filled fenders add extra protection in tough zones. Tugboats, camels, and mooring lines help control movement and secure the sub. For repairs, dry docking offers full support with keel blocks and precise control.

Together, smart equipment and well‑planned steps let crews dock submarines safely and keep them ready for service.