How to Implement the STS(Ship to Ship) Operation.

07/20/2021

Foam Filled Fender

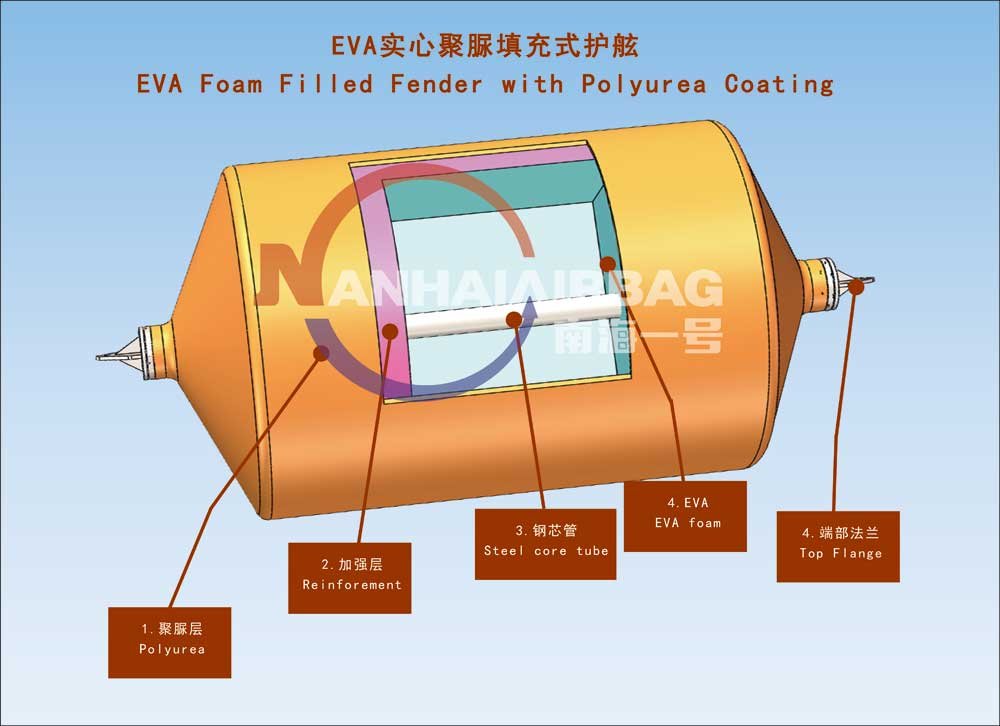

If you look into the components of a foam fender, it consists of an internal steel core, closed cell foam, reinforced cord layers, and then an outer elastomer skin.

The outer elastomer skin is usually made of the anti-corrosive PU (polyurethane).

In general, for marine use, the ‘closed cell foam’ used in these fenders are usually materials like EVA (Ethylene-vinyl acetate) or PE (Polyethylene).

- EVA foam is quite an environmentally-friendly plastic packaging material, relatively new.

- PE foam is a high-molecular low density foam material.

Both materials are first and foremost, anti-water absorption. Which means they do not absorb water, making them perfect for marine use. Besides, both generally provide efficient energy absorption, good chemical corrosion resistance.

- EVA foam is quite an environmentally-friendly plastic packaging material, relatively new.

- PE foam is a high-molecular low density foam material.

Both materials are first and foremost, anti-water absorption. Which means they do not absorb water, making them perfect for marine use. Besides, both generally provide efficient energy absorption, good chemical corrosion resistance.

Weight to absorption ratio are both reasonably good, hence their usage as fenders. If the weight is too heavy, they would be hard to deploy.

It has good moisture insulation, cushioning, chemical corrosion resistance, etc., and it has no water absorption.

It has good moisture insulation, cushioning, chemical corrosion resistance, etc., and it has no water absorption.

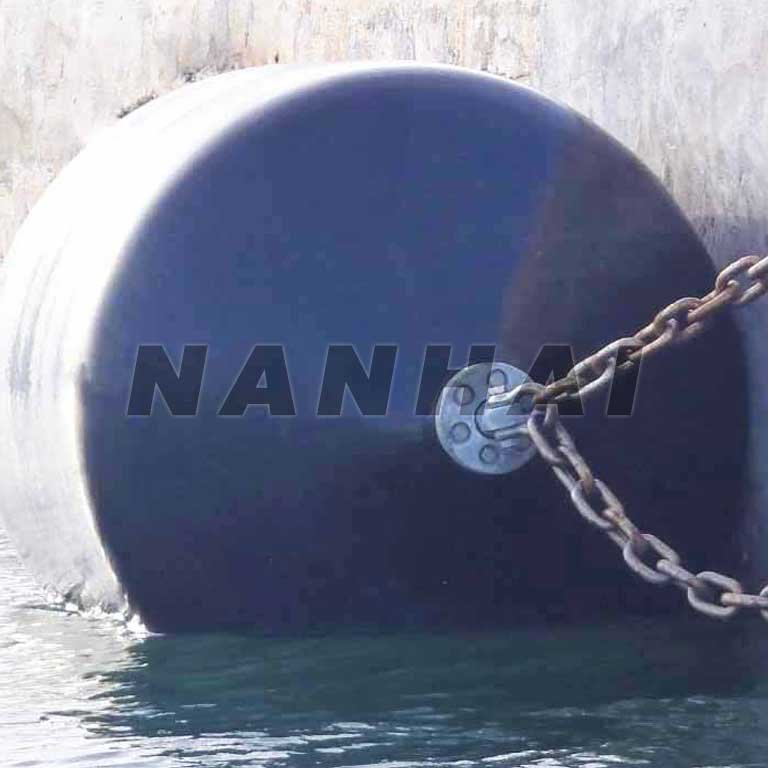

Yokohama type Pneumatic Rubber Fender

Pneumatic fenders are made of rubber and strengthening cord layers. These are inflated to absorb collision energy during berthing.

Similar to foam fenders, these rubber floating fenders are also relatively light (for its size), and provide great cushioning due to its pneumatic properties.

To compare the two, we have to look into different aspects of their usage:

丨 Performance

Performance wise, some claim that foam fenders is more efficient in terms of energy absorption. There are reports of foam-filled fenders that absorb 40% more energy than pneumatic fenders. However, performance of foam fenders really depends on the manufacturer.

We have heard cases of customers using foam fenders that deformed easily during operation. Once deformed, the fender is not suitable for use any more. Not only the energy absorption is not efficient, it may even damage the vessels or harbour.

Therefore, it is important to not blindly assume that all foam fenders are better in performance. It is better to check and order from a manufacturer with a strong track record of delivering great products.

At NanHai, our foam fenders have been used for various projects globally in countries in more than five continents.

If you require a foam fender solution, contact us!

丨 Durability

Durability is harder to gauge. Do you define by useful life?

This is not an accurate benchmark as the conditions of deployment (working conditions) and usage rate is not taken into account.

However, one obvious advantage a foam-filled type has over a pneumatic rubber fender is that they do not deflate.

When Yokohama-type pneumatic fenders got punctured, they fail to perform any more. Whereas for foam fenders, they would still be able to be deployed, albeit having much less efficient energy absorption.

At the very least, they could still be used sparingly for temporary purposes.

NanHai pneumatic fenders generally last more than 10 years, similarly with foam fenders.

丨 Maintenance

Both foam-filled fenders and pneumatic fenders require minimum maintenance. Regular visual inspection is a must for both fender types.

For pneumatic fenders, just add in the air addition regularly (probably around 12 months). Nevertheless, both are low maintenance equipment if you purchase from the right manufacturer.

So in this area, it can be said it is primarily a tie, with foam fender a slight edge over pneumatic.

丨 Price

This is where rubber floating pneumatic fenders have a considerable advantage over foam fenders. For the same size, foam-filled fenders may cost up to 3x more expensive than their pneumatic counterparts. This is because pneumatic fender’s primary component is air, which is essentially free.

However, the outer layer that holds the air has to be strong enough to efficiently absorb energy upon collision and transfer it to the air, while repelling the excess energy back as reaction force.

On the other hand, for foam fenders, it is the ultra-efficient closed-cell foam core that absorbs fully the energy (repel the excess energy back as reaction force). Hence, the amount of materials used is much more than the rubber, for a similar sized fender.

丨Conclusion

When determining whether to use pneumatic type or foam-filled type for your floating fender needs, it is important to consider your budget as well as expectations.

Generally smaller sized fenders like for those below diameter 2.0m, foam fenders are still at a manageable cost that still provides slightly more superior performance.

However, for jumbo sized very large-sized fenders, the costs will increase to a much bigger value. That is when most consider using pneumatic rubber fender for large ship-to-ship berthing operations.

Both foam-filled fenders and pneumatic fenders require minimum maintenance. Regular visual inspection is a must for both fender types.

For pneumatic fenders, just add in the air addition regularly (probably around 12 months). Nevertheless, both are low maintenance equipment if you purchase from the right manufacturer.

So in this area, it can be said it is primarily a tie, with foam fender a slight edge over pneumatic.

丨 Price

This is where rubber floating pneumatic fenders have a considerable advantage over foam fenders. For the same size, foam-filled fenders may cost up to 3x more expensive than their pneumatic counterparts. This is because pneumatic fender’s primary component is air, which is essentially free.

However, the outer layer that holds the air has to be strong enough to efficiently absorb energy upon collision and transfer it to the air, while repelling the excess energy back as reaction force.

On the other hand, for foam fenders, it is the ultra-efficient closed-cell foam core that absorbs fully the energy (repel the excess energy back as reaction force). Hence, the amount of materials used is much more than the rubber, for a similar sized fender.

丨Conclusion

When determining whether to use pneumatic type or foam-filled type for your floating fender needs, it is important to consider your budget as well as expectations.

Generally smaller sized fenders like for those below diameter 2.0m, foam fenders are still at a manageable cost that still provides slightly more superior performance.

However, for jumbo sized very large-sized fenders, the costs will increase to a much bigger value. That is when most consider using pneumatic rubber fender for large ship-to-ship berthing operations.