Floating Foam Fenders

07/16/2017Floating Pneumatic Fenders

Pneumatic Rubber Fenders are fast and easy to install, keeping suitable clearances between the hull and the jetty or vessels. These ship fenders played a critical role on the safe operation of ship berthing.

NANHAI PNEUMATIC RUBBER FENDER SHOWROOM

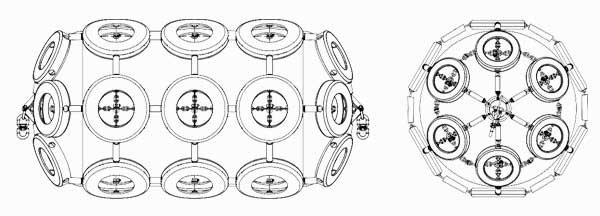

Constructed with several layers of strong tyre cord arranged at optimum angles, Yokohama's floating pneumatic rubber fenders are designed to distribute load and stress evenly. Extremely resistant to pressure and cutting, they are able to withstand abrasion during adverse weather conditions meaning they are ideally suited to harsh marine environments. Larger sized fenders also come fitted with a safety valve as an added precaution to prevent accidents in the situation of over compression.

Reliant on the compressive elasticity of air, Yokohama pneumatic rubber fenders show no deterioration or variation in performance due to fatigue or extremely low temperatures (-50°C and below) thereby negating the need for owners to make regular replacements.

Installation is simple and inexpensive, fender is supported by its own weight in the water. As such, it can be moored easily by means of a guy rope or chain, it can be removed with ease for transfer to another mooring point.

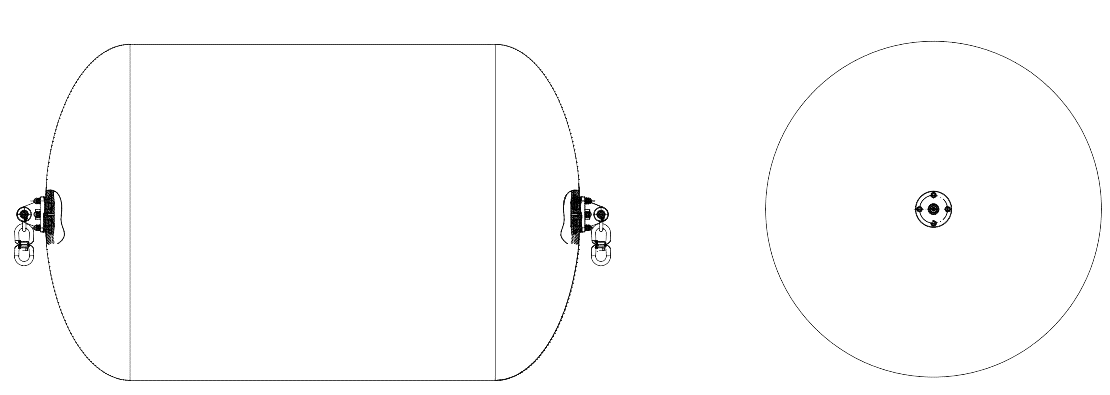

Pneumatic Rubber Fenders' diameter is 300 mm minimum and the maximum will be 4,500 mm. The range of lengths are 500 mm to 9,000 mm, as well as special sizes. The sling-type or chain & tire net(CTN) are available for both sizes.

The colors are usually be black and grey (Navy), if you need more we would like offer customized service.

CONTACT NANHAI

Send as a message via contact form

For better communication , please leave your contact number for us in below.

SUCCESSFUL CASE

Customer:

UAE Logistic Company

Application:

STS (Sand Transportation)

Pneumatic Rubber Fender:

4.5m*6m,Sling Type

Quantity: 6 Pcs

Customer:

Brazil Oil & Gas Company

Application:

Ship to dock berthing

Pneumatic Rubber Fender:

4.5m*6.4m,Sling Type

Quantity: 25 Pcs

Customer:

USA Logistic Company

Application:

Dock berthing

Pneumatic Rubber Fender:

3.3m*6.5m,CTN Type

Quantity: 25 Pcs

Customer:

Marine Products Distributor

Application:

In Stock

Pneumatic Rubber Fender:

1.2*2m 1.5*3m 2*3.5m 2.5*5.5m

Quantity: 97 Pcs