How to Choose the Right Floating Airbags for Your Project

07/02/2025Foam Fender: Choosing the Best Protection

07/03/2025The Best Materials for Salvage Airbags

1. Introduction

Salvage airbags play a key role in many marine operations. Workers use them to lift sunken vessels, move heavy equipment, and carry out underwater rescue missions. Because these jobs often involve high risk, airbags must be strong and dependable. Over the years, airbag materials have evolved to meet these growing demands. From PVC to multi-layer rubber, the shift reflects progress in both safety and performance.

2. Why Material Matters in Salvage Airbags

Material choice affects everything—pressure capacity, wear resistance, and service life. A poor-quality material can lead to sudden airbag failure during critical operations. In contrast, the right material ensures stability and protects both workers and equipment. Therefore, understanding the role of materials is not just helpful; it’s essential.

3. Early Materials: PVC and Nylon-Coated Fabrics

In the early days, manufacturers used PVC and nylon-coated fabric to produce salvage airbags. These materials were affordable, lightweight, and easy to transport. However, they came with many drawbacks. For example, they had low pressure resistance, tore easily, and offered poor durability in saltwater. As a result, they were only suitable for light tasks in calm or shallow environments.

4. The Shift to Rubber-Coated Fabrics in Salvage Airbags

To meet greater demands, the industry moved toward rubber-coated fabrics. These included natural rubber and synthetic types like SBR (Styrene-Butadiene Rubber). Rubber provided much higher elasticity and could handle higher pressures. It also improved resistance to UV exposure, chemicals, and abrasion. Thanks to these advantages, rubber airbags replaced PVC in many medium-duty marine projects.

5. The Modern Standard: Multi-Layer Reinforced Rubber

For high-load operations, today’s best choice is the multi-layer reinforced rubber airbag. This design combines:

- An inner rubber layer to keep the air sealed

- Reinforcement layers made of polyester or Kevlar to support high pressure

- An outer rubber layer for protection against damage from rocks, saltwater, or sunlight

Because of this structure, multi-layer airbags are far more durable than earlier models. They also meet important certifications such as ISO 14409 and CCS, which ensure they’re safe for use in commercial marine jobs.

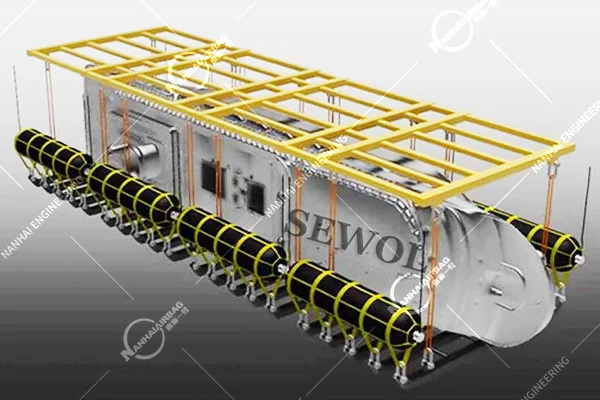

6. Advanced Manufacturing: Holistic Screw Technology

Our Vessel Salvage Airbags use an advanced method called Holistic Screw Technology. This process forms a single, enclosed tube with cone-shaped ends. There are no welded seams, which greatly improves strength and safety. Unlike RF-welded airbags, which may fail at the seams, these seamless airbags perform better under pressure. Furthermore, their structure allows for longer service life and better resistance to environmental stress.

7. How to Choose the Right Salvage Airbags Material

Not every project needs the most advanced material. Choosing the correct type depends on weight, water depth, and working conditions. Here’s a basic guide:

| Project Type | Recommended Material | Why |

|---|---|---|

| Small fishing boat lifting | PVC or nylon-coated fabric | Low cost, easy handling |

| Medium salvage operation | Rubber-coated fabric | Good pressure and durability |

| Heavy salvage projects | Multi-layer reinforced rubber | High strength, safety under extreme conditions |

Always choose multi-layer reinforced rubber airbags for critical or deep-sea projects. Their strength and stability make them the safest option.

8. FAQs About Salvage Airbags Materials

Q: Why is rubber better than PVC for salvage airbags?

Rubber can handle more pressure, resist damage, and last longer in tough environments.

Q: Can I reuse salvage airbags?

Yes. With proper maintenance, rubber airbags—especially multi-layer ones—can be reused multiple times.

Q: Are seamless airbags really stronger?

Absolutely. Seamless airbags avoid the weak points found in welded seams, making them more reliable.

Q: Do airbag materials require different storage care?

They do. For example, rubber must be stored away from sunlight and chemicals to avoid aging.

9. Conclusion

The evolution of salvage airbags—from PVC to multi-layer reinforced rubber—shows how technology has responded to real-world marine needs. Each new step in material improvement brought better pressure resistance, longer life, and higher safety. Holistic Screw manufacturing takes it even further by removing weak points like seams and adding extra strength to the airbag body.

When you’re working on a critical marine operation, don’t take chances with poor-quality materials. Choose strong, tested, and certified airbags that match your job’s demands.

Trust better materials. Choose safety. Ensure success.