Can I add a tire net to the existing pneumatic fenders?

08/12/2025What is the function of UHMW-PE sheet on rubber fenders?

08/13/2025When Are Hydropneumatic Fenders Necessary?

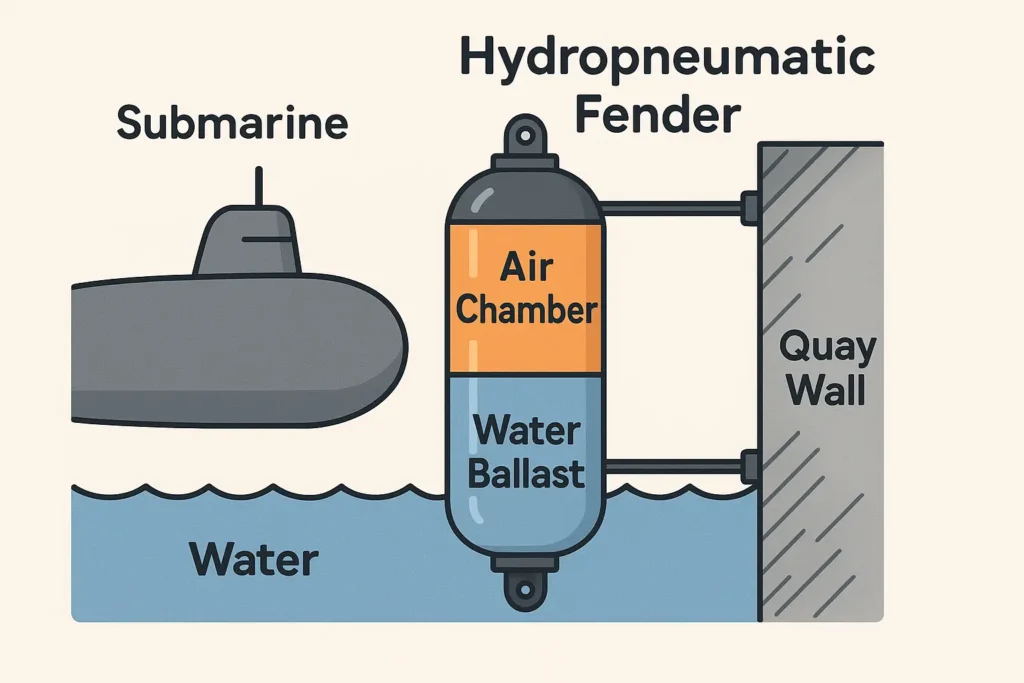

Hydropneumatic fenders are not something you see on every dock. They’re a specialized type of fender designed for unique berthing situations—especially when a standard pneumatic or foam-filled fender won’t do the job. If you’ve ever wondered why submarines and certain special vessels use them, or when they become absolutely necessary, this guide breaks it all down.

What Are Hydropneumatic Fenders?

A hydropneumatic fender is a cylindrical or conical floating fender that uses both air and water as energy-absorbing media. It’s installed vertically (or semi-vertically) so that part of it stays submerged below the waterline.

- Air chamber – absorbs impact with elasticity, much like a pneumatic fender.

- Water ballast – stabilizes the fender, controls the contact point, and keeps it at the correct depth.

Because they combine buoyancy control with energy absorption, hydropneumatic fenders can align perfectly with a vessel’s hull—whether that hull sits deep below the waterline or has delicate equipment like sonar domes.

When Are Hydropneumatic Fenders Necessary?

You don’t need hydropneumatic fenders for every ship docking. But there are certain scenarios where they’re the safest—and often the only—option.

1. Submarine Berthing

Submarines have curved hulls and sensitive sonar domes located below the waterline. Standard fenders can’t make safe contact without risking damage. Hydropneumatic fenders maintain a constant contact height below the waterline, cushioning the submarine gently during berthing.

2. Vessels with Low Freeboard or Curved Hulls

Ships with unusual hull geometry—like naval support vessels or research ships—may not align well with standard fenders. Hydropneumatic fenders adjust to meet the hull at the right point every time.

3. Ports with Large Tidal Ranges

In areas with significant tidal variation, a fixed or standard floating fender can cause the contact point to drift dangerously. Hydropneumatic fenders use ballast water to keep the strike zone steady, even as the tide rises or falls.

4. Protection for Sensitive Equipment

Some vessels carry external sensors, cable ports, or delicate structures. The low reaction force of hydropneumatic fenders minimizes shear and point-loading, reducing the risk of costly damage.

5. Confined Berths and Docking Bays

In naval bases or shipyards with tight docking spaces, fenders must stay in a precise position. Hydropneumatic units can be mounted on guide rails or chains to ensure vertical alignment.

How to Specify Hydropneumatic Fenders

When designing a berthing solution, these are the main factors to consider:

- Energy Absorption (E) – How much kinetic energy the fender can safely absorb during contact.

- Reaction Force (R) – The maximum force exerted on the vessel’s hull.

- Deflection Range – The amount the fender compresses during impact.

- Effective Contact Height – How deep below the waterline the fender maintains contact.

- Air/Water Ratio – Adjusted to suit the vessel’s draft and expected berthing conditions.

Installation Methods

Hydropneumatic fenders are usually mounted vertically using:

- Guide rails – Allow controlled vertical movement.

- Chain systems – Secure the fender in place while allowing some movement.

- Counterweights – Keep the fender at the designed depth.

Installation should ensure there’s enough clearance for the fender to compress without contacting fixed structures.

Hydropneumatic Fenders vs. Other Fender Types

| Feature | Hydropneumatic Fenders | Pneumatic Fenders | Foam-Filled Fenders |

|---|---|---|---|

| Contact Point Control | Adjustable, fixed depth | Floating, varies | Floating, varies |

| Reaction Force | Low, controlled | Medium | Medium |

| Energy Absorption | High | High | Medium-High |

| Suitable for Submarines | ✅ | ❌ | ❌ |

| Maintenance | Moderate | Low | Low |

Real-World Applications

- Naval Bases – Submarines and specialized warships rely on hydropneumatic fenders for safe berthing in sensitive zones.

- Shipyards – Deep-draft vessels with hull equipment use them during maintenance and launch.

- Research Vessels – Oceanographic ships with underwater instruments avoid damage by using low-reaction hydropneumatic systems.

Operation & Maintenance

- Daily checks – Air pressure, water ballast levels, and visual inspection.

- Scheduled maintenance – Replace seals, check inflation valves, and inspect attachment points.

- Extreme conditions – Ensure fenders are not over-compressed or exposed to damaging currents.

Common Mistakes to Avoid

- Using standard pneumatic fenders for submerged contact – Risks hull or equipment damage.

- Ignoring tidal range – Leads to misaligned contact and potential accidents.

- Choosing by energy absorption alone – Reaction force and shear resistance are just as important.

FAQ

Q1: What are hydropneumatic fenders used for?

They’re designed for vessels like submarines that need a controlled contact point below the waterline.

Q2: Why are they essential for submarines?

They match the submarine’s hull curve and avoid damaging sensitive sonar domes.

Q3: How do they handle large tidal ranges?

By adjusting the air/water balance, they keep the contact point steady regardless of tide height.

Q4: Are they difficult to maintain?

Not particularly—just follow a routine check for pressure, water ballast, and seals.

Conclusion

Hydropneumatic fenders are a niche but vital solution for berthing submarines, vessels with special hull shapes, and ships operating in areas with large tidal ranges. Their ability to control the contact point, reduce reaction force, and protect sensitive equipment makes them indispensable in certain ports and naval facilities.

If you’re designing a berth for a submarine or specialized vessel, hydropneumatic fenders should be at the top of your shortlist.