How Ship Berthing is done Using Marine Fenders ?

08/18/2025Foam Filled Fenders in Indonesia

08/19/2025What is the berth port of a ship?

If you have ever wondered what a berth port is, you are not alone. In the shipping world, the term berth can sometimes cause confusion because it carries more than one meaning. For seafarers, a berth might mean a bed on board. For navigators, it could describe a safe distance. However, for port engineers, shipping companies, and most people working around harbors, berth port refers to a very specific thing: a designated spot in the harbor where a ship can safely dock, load, or unload cargo.

In this article, we will clearly explain what a berth port really means, its key components, how ships use it, and why it plays a central role in global trade.

1. Quick Definition: What Is a Berth Port?

A berth port is a designated location within a port or harbor where a ship moors (ties up), either alongside a quay, jetty, or mooring dolphins. In simple words, it is the “parking space” for vessels. Each berth port includes facilities built for certain ship sizes and cargo types, such as container ships, oil tankers, bulk carriers, or passenger ferries.

Think of it as the official parking bay for your car—but on a much larger scale and with more engineering behind it.

2. Why Is a Berth Port Important?

Modern ports are busy hubs that manage thousands of ships every year. Therefore, without properly designed berths, global shipping would face chaos.

- Efficient cargo handling – Berths include cranes, pipelines, and loading systems that speed up trade.

- Safety of ships and crew – Mooring points, bollards, and fenders keep vessels secure.

- Traffic management – Organized berths reduce congestion and prevent costly delays.

- Adaptation to vessel size – Different berths serve small boats, bulk carriers, or even LNG carriers.

As a result, berth ports act as the backbone of daily port operations.

3. Key Components of a Berth Port

A modern berth port is not just empty water. Instead, it combines infrastructure and safety systems that make docking possible.

3.1 Quay, Jetty, or Wharf

This is the solid structure where the ship docks. It creates the physical connection between land and ship.

3.2 Marine Fenders

Fenders absorb the energy of a ship during berthing. In other words, they protect both the quay and the ship’s hull from damage.

3.3 Mooring Equipment

Bollards, hooks, fairleads, and mooring dolphins secure the ship once it arrives.

3.4 Utilities and Services

A berth port often provides shore power, fresh water, fueling, firefighting systems, and cargo-handling cranes.

3.5 Navigation and Safety Aids

Lighting, buoys, and pilot services guide ships safely into the berth.

4. How a Ship Uses a Berth Port (Berthing Process)

When a vessel arrives at a harbor, the berthing process usually follows several clear steps:

- Pre-arrival communication – The ship notifies the port authority and receives berth allocation.

- Pilot boarding – A marine pilot boards the vessel and guides it into the berth.

- Tug assistance – Tugboats help control the ship’s movement and reduce the risk of accidents.

- Approach and mooring – The ship approaches slowly, fenders absorb the impact, and mooring lines secure the vessel to bollards.

- Operations – Cargo loading, unloading, or passenger transfer begins immediately after safety checks.

Therefore, each stage ensures that the ship can dock efficiently and without damage.

5. Different Types of Berth Ports

Not all berths serve the same purpose. In fact, ports design them according to vessel type:

- Container Berths – Equipped with gantry cranes to handle containers.

- Bulk Cargo Berths – Built for grain, coal, ore, or cement.

- Oil & Gas Berths – Include pipelines, loading arms, and strict safety systems.

- Passenger Berths – Designed for cruise ships and ferries, with passenger terminals.

- Multipurpose Berths – Handle mixed cargo when flexibility is required.

This variety allows ports to serve global trade more effectively.

6. Berth Port vs. Other Meanings of “Berth”

It is easy to confuse the word “berth.” However, each meaning applies to a different context:

- Berth Port – Docking space in a harbor.

- Berth (Bed) – Sleeping place for crew or passengers.

- Wide Berth – A safe distance kept from another vessel.

Consequently, when people in shipping mention “berth port,” they almost always mean the designated docking space in the harbor.

7. How Berth Ports Use Fenders and Mooring Equipment

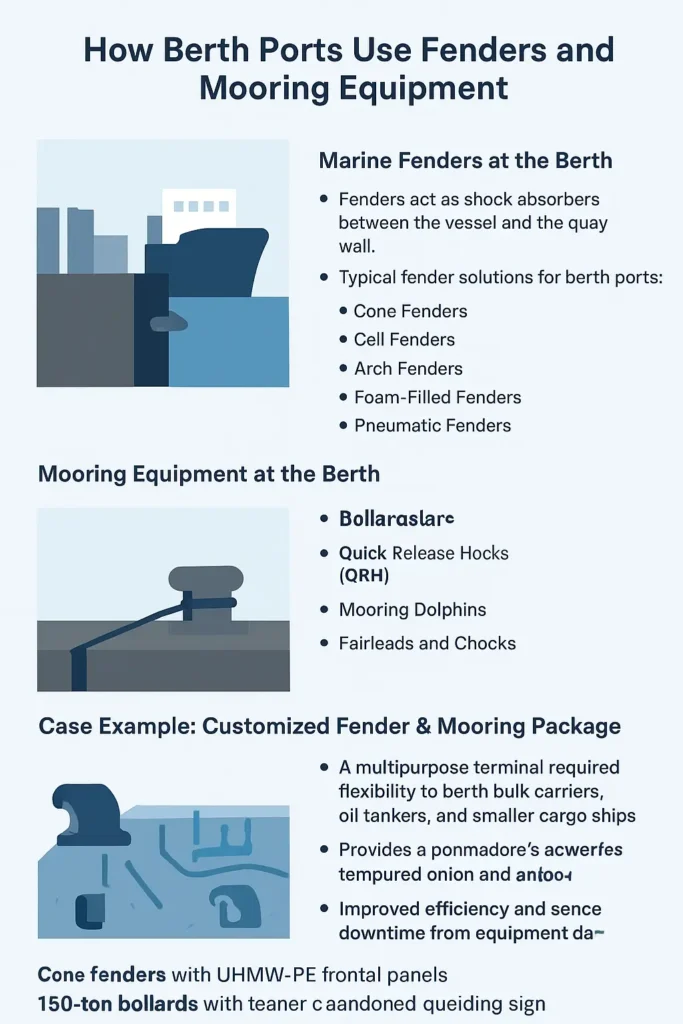

When we talk about a berth port, one of the most critical parts is the protective and mooring system. Without the right fenders and bollards, even a perfectly designed berth cannot guarantee safe berthing. This is exactly where our company’s expertise comes in.

7.1 Marine Fenders at the Berth

Our fenders act as shock absorbers between the vessel and the quay wall. When a ship approaches the berth, the energy from contact transfers into the fender instead of damaging the ship or port infrastructure.

Typical fender solutions for berth ports include:

- Cone Fenders – High energy absorption, suitable for large vessels and container terminals.

- Cell Fenders – Widely used for oil and bulk terminals, known for stability and long service life.

- Arch Fenders – Compact design for small to medium ships, economical and easy to install.

- Foam-Filled Fenders – Floating design, ideal for multipurpose berths and frequent operations.

- Pneumatic Fenders – Common in temporary or offshore berths, offering flexibility and ease of handling.

By matching fender type with berth design, ports reduce maintenance costs and extend the lifespan of both the berth and the vessel’s hull coating.

7.2 Mooring Equipment at the Berth

Once the vessel makes contact, mooring equipment keeps it secure during loading or unloading. Our solutions cover the full range of berth mooring needs:

- Bollards – Strong cast steel structures for fixing mooring lines. Available in T-head, Horn, and Kidney shapes to match different rope angles.

- Quick Release Hooks (QRH) – Designed for modern terminals where fast and safe line handling is required.

- Mooring Dolphins – Installed when direct quay structures are not possible; they provide secure mooring points offshore.

- Fairleads and Chocks – Guide ropes correctly, reduce friction, and protect both ropes and ship structures.

When combined with well-designed fenders, these systems allow ships of all sizes to berth smoothly and operate safely.

7.3 Case Example: Customized Fender & Mooring Package

For one of our recent projects, a multipurpose terminal required flexibility to berth bulk carriers, oil tankers, and smaller cargo ships. We provided a full package:

- Cone Fenders with UHMW-PE frontal panels to reduce hull pressure.

- 150-ton T-head bollards positioned for multiple mooring line angles.

- Quick Release Hooks to improve turnaround safety.

As a result, the berth port improved efficiency and reduced downtime from equipment damage.

👉 With the right combination of fenders and mooring equipment, a berth port becomes a safe, efficient, and long-lasting part of port infrastructure.

8. Common Questions About Berth Ports (FAQ)

Q1: Is a berth the same as a port?

No. A port is the whole facility, while a berth is just one docking position inside the port.

Q2: How many ships can a berth handle?

Usually one at a time, but large terminals may operate several berths simultaneously.

Q3: Do all ships fit into any berth port?

No. Each berth is designed for specific dimensions—length, width, and draft of ships.

Q4: What role do fenders play in a berth port?

Fenders act as shock absorbers. They protect both the vessel and the quay from impact damage.

Q5: Can a berth port be upgraded?

Yes. Ports often upgrade berths with stronger fenders, deeper water, or larger cranes to handle bigger ships.

9. Conclusion

A berth port is far more than a simple parking spot for ships. It combines engineering, safety, and efficiency to keep world trade moving. Moreover, it ensures that cargo transfers happen quickly and securely, while ships remain protected from damage.

Whether you are a port engineer, a ship operator, or simply curious about maritime logistics, understanding the role of a berth port gives you a clearer view of how complex modern shipping really is.

So, the next time you watch a ship docking, remember: the berth port is the carefully designed stage that makes the entire operation possible.