Are foam filled marine fenders recyclable?

08/15/2025What is the berth port of a ship?

08/18/2025How Ship Berthing is done Using Marine Fenders ?

If you’ve ever watched a huge ship slowly edge toward a port, you might have wondered: what keeps all that steel from smashing into the quay? The answer lies in something simple but clever—marine fenders. These systems are the unsung heroes of every safe berthing operation.

In this guide, we’ll walk through what marine fenders are, how they work during berthing, the step-by-step process ships follow, and why choosing the right fender makes all the difference.

How marine fenders work during berthing

Here’s the physics in plain language:

- As the ship approaches, it carries kinetic energy (mass × velocity²).

- When the hull meets the fender, the fender compresses.

- This compression absorbs energy and pushes back with a controlled reaction force.

- The ship slows down and comes to rest safely alongside the quay.

A good fender provides high energy absorption but keeps reaction forces low—protecting both vessel and quay.

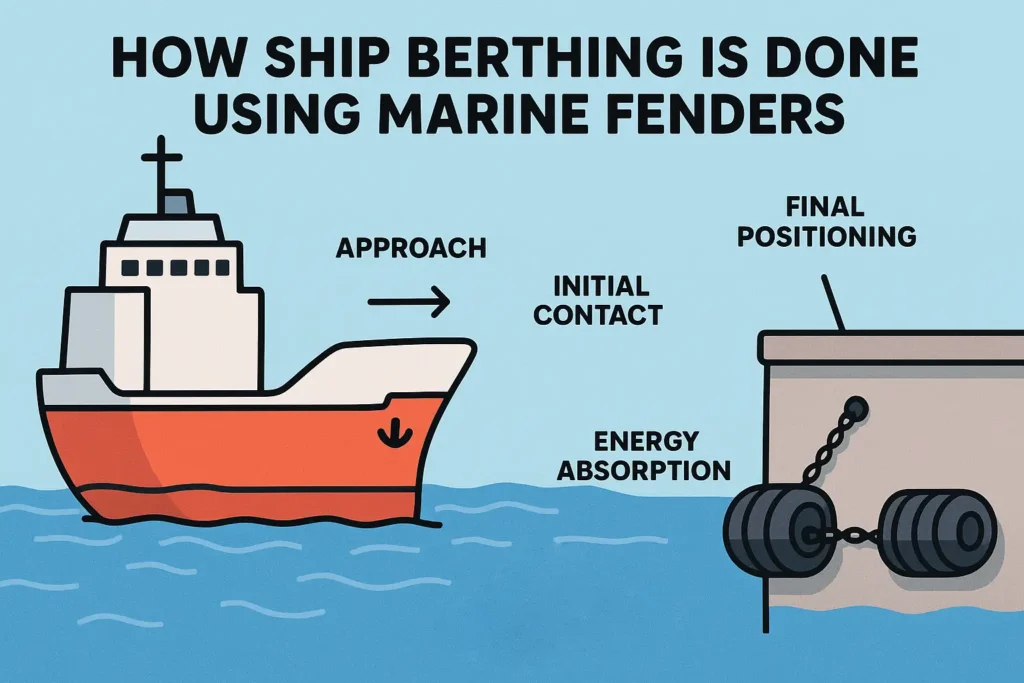

The step-by-step berthing process with fenders

Berthing isn’t random—it follows a clear sequence:

- Pre-arrival planning – Pilots and port staff check the vessel’s size, draft, weather, and tidal conditions.

- Approach – Tugs help guide the ship while keeping speed and angle under control.

- Initial contact – The first fender makes contact, cushioning the ship’s side.

- Energy absorption – Fenders compress, spreading the load and slowing the ship.

- Final positioning – Once movement stops, mooring lines are tightened.

- Post-berthing check – Crew and dock staff inspect fenders and ensure everything is secure.

Without fenders in place, even a small miscalculation could result in expensive repairs.

Why marine fenders matter in ship berthing

Berthing a ship isn’t just “parking” a vessel. Ships can weigh thousands of tons, and even at low speeds, the kinetic energy during berthing is massive. Without proper energy absorption, that energy would be transferred directly to the quay or the ship’s hull—leading to dents, cracks, or worse.

That’s where marine fenders come in. They cushion the impact, absorb the energy, and spread the load so both ship and berth stay safe.

What exactly are marine fenders?

At their core, marine fenders are energy absorbers. They take the kinetic energy of a moving vessel and convert it into a safe reaction force. Think of them like the bumpers on a car—only much larger and engineered for extreme loads.

Types of marine fenders

Different berths and ships need different protection. Common types include:

- Pneumatic fenders (often called Yokohama fenders): large inflatable units, great for ship-to-ship or temporary berthing.

- Foam filled fenders: tough outer skin with a resilient foam core, often used offshore.

- Solid rubber fenders: fixed to quays, including cone, cell, arch, cylindrical, and element fenders.

- Hydropneumatic fenders: a mix of air and water inside, used for submarines or vessels with varying draft.

Components of a fender system

Many quay-mounted fenders also include fender panels with UHMW-PE pads on the front. These panels spread the load and reduce friction so a ship’s paintwork doesn’t get scratched off.

Choosing the right marine fenders

Not all fenders suit every vessel. The right choice depends on:

- Ship size and displacement

- Approach velocity

- Berthing angle

- Tidal variation

- Quay structure

Matching fender to vessel type

- Cone or cell fenders – best for large ships with heavy berthing energy.

- Arch or cylindrical fenders – common at workboat and small vessel berths.

- Pneumatic or foam filled fenders – flexible, portable, and good for uneven hulls or offshore operations.

- Hydropneumatic fenders – specialized for submarines.

Fender layout and installation

Proper layout ensures continuous protection along the quay. Spacing and height are designed to cover tidal variations. Panels with UHMW-PE facing reduce friction, while chains and anchors keep fenders secure. Corners, ramps, and dolphins often need special arrangements.

Best practices for safe berthing

- Keep approach speed within limits.

- Use tugs where needed.

- Ensure clear communication between ship, pilot, and port staff.

- Avoid berthing in unsafe weather conditions.

FAQs about marine fenders

Do marine fenders work for all vessel sizes?

Yes, but the type and size must match the vessel’s berthing energy.

Will foam filled fenders damage ship paint?

Not if they’re fitted with proper polyurethane skin and smooth surfaces.

How often should fenders be inspected?

Before critical calls and at regular maintenance intervals.

Conclusion

Berthing a ship safely is all about managing energy. Marine fenders make this possible by absorbing impact, reducing stress on quays, and protecting hulls. Whether it’s a small tugboat or a massive cargo vessel, fenders are the quiet guardians of every safe docking.

If you’re planning a new berth or upgrading your system, choosing the right marine fender setup will ensure smooth operations and lower maintenance costs in the long run.